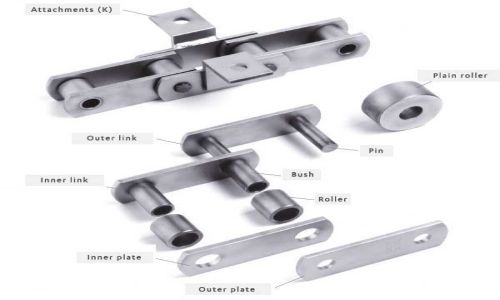

Bagasse Carrier Chain – Feed bagasse to Boiler or to Storage Point

Drop Forged Chain – Feed Canes into the Cane Washing sections

Fabricated Rake Carrier Chain – SS made, corrosion resistant

Inter Carrier Chain – A versatile chain used in all the process works

Sugar Bag Stacker Chain – Higher speeds and higher efficiencies

Conveyer belts are hugely used for loading and unloading systems for packing, transportation system for materials in different sections of sugar plant. Several non-contact sensors are situated above the belt to monitor the profile of the material on the conveyor belt. Salient features are: Longer working life with high conveying capacity and easy mobility of material. Should be robust and have high tensile strength with wear and tear resistant.

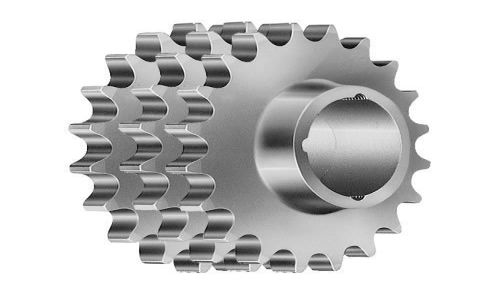

Sprockets manufactured from good quality cast iron or fabricated steel. For arduous duty, it may be necessary to use steel sprockets having a high carbon content. For extremely arduous duty the tooth flanks should be flame hardened. There are other materials which may be specified for particular requirements. Sprocket material varies depends upon normal conditions to heavy shock conditions. Three types of sprockets are cast, segmented and split.

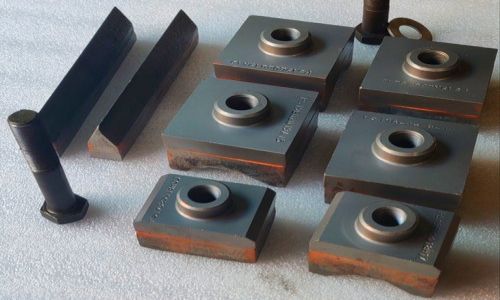

Slats are subjected to operations like Blanking, Piercing & Shaving, which are carried out on highly Precise Presses. Further links are Hardened & Tempered to avoid linear elongation & to get better strength, followed by shot penning to improve the fatigue strength. Our slat profile are accurately formed for proper overlapping on 600 ton capacity heavy duty hydraulic presses. Slates are easy for interchangeability & replacement. Slate holes are precisely punched to suit chain attachments.

Standard sugar mill practices limit the bearing pressure to about 10 MPa. The bronzes that are common in sugar mills have a recommended maximum bearing pressures of up to 100 MPa for phosphor bronze and 50 MPa for tin-bronzes. These materials along with Gun metal, White metal and some copper-based alloys were made in compliance to the IS and BS standards, these are appreciated for their resistance against abrasion and durability.

Depending on your gearbox model, our engineers can often conduct repairs in situ to reduce downtime to its lowest level. If your gearbox cannot be repaired at site, our proposals team will strive to minimize the costs associated with removing your gearbox from its application and upgrade recommendations for gearboxes experiencing serial failure. Gearbox spares were used at Mill & Diffuser drives, Cooler drives, knife drives, Centrifuge & Shredder drives, Rotary vacuum filter drives and Generator drives.

Gears and Pinions are spare parts used in chain to keep milling house and industry running. We design gears of various types like helical, worm, and also for specific applications by using latest technology resistant to wear and tear with high quality steel. With numerous heat treatment techniques the hardness of tooth tip will enhanced resulting tough wear and tear resistance and fatigue loads.

Made of wear-resistant steel and reduces bagasse moisture. Eliminates problems of re-absorption of juice in bagasse.

Corrugated Roller Shells – Resistance against slipping

Dimpled Roller Shells – High surface friction for better division of raw material elements

Perforated Roller Shells – Maximum extraction of cane juice

Other types are of Top, Bottom and underfeed Roller Shells

Sugar mill knife chopper, cutter, leveler and mincer attachments available in various sizes. Variants with Double “V” Edge and Flat Edge welded to the knife body shanks are also available

Sand (silica) and other abrasive materials harvested with sugarcane causes severe wear on shredder/ fibrizor hammers. Replacing these hard-facing parts can substantially reduce wear, giving considerable savings in down time and lost production. Made of composite consisting of complex carbides in a metallic matrix. Metallurgically bonded to a mild steel backing plate. Carbides have a minimum hardness of 770 Hv to maximum of upto 1500 Hv. Extremely strong abrasion resistant and corrosion resistant. Special grade welding for adding extra strength.

Sugar mill requires Trash beam, Trash plate, Scrappers. These are frequent wearing spares and are made of high-quality raw material with quick hitch adaptability and easy installation. These are made of corrosive resistant cast metal adhering to international standards.

Sugar industry requires corrosion free and wear resistant metallic valves and should be approved by international standards. Valves are used to direct or control the flow of sugar juice, water and regulating the pressure at the boiler.

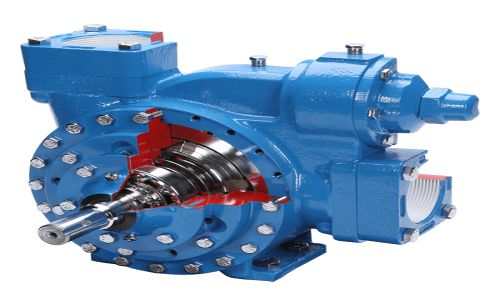

In sugar Industry Pumps are used at multiple stages from non-premising sugar cane to factory made sugar crystals at the final stage of filling and packaging point. Pumps are necessary at various stages of Colour precipitant, Flocculants, Fullers earth slurry, Lime slurry, Magma, Massecuite, Melt, Molasses of different stages, Phosphoric acid, Press mud, Raw cane fiber, Sludge, Sulphited syrup and thick juice.

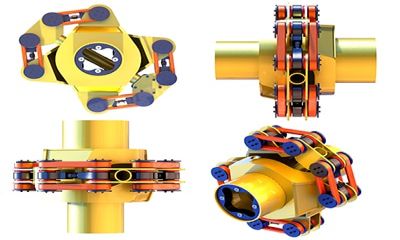

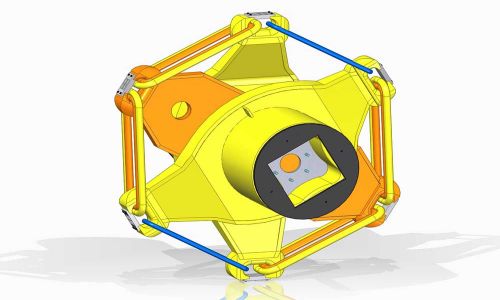

Multi mis-alignment coupling replaces square coupling, polyester slings were used in this coupling hence called as rope coupling. The design is completely flexible and absorbs a large amount of shocks and mis-alignments of top roller mill with respect to the output shaft of the driving gear. the Mill operates at the designed setting and optimum hydraulic pressure and consequently performs more efficiently with negligible maintenance.