Carrying cane into sugar mill involves multi stage handling. We equipped to provide Cane unloader, Eot cranes, Cane Kicker, Cane Cutter, Fibrizor, Shredders, Chopper, Feeder tables, Cane Carriers as per the tonnage requirements and space allocations for the cane handling system. Cane unloader with 2/3 motion electrical or hydraulic driven.

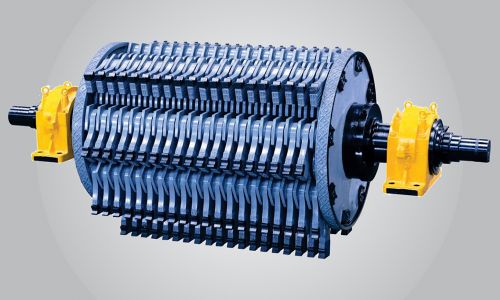

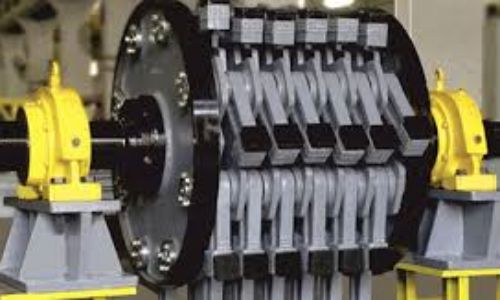

Fibrizers and Shredders with hammers of replaceable tips. We design according to the specific needs with variable frequency drive system.

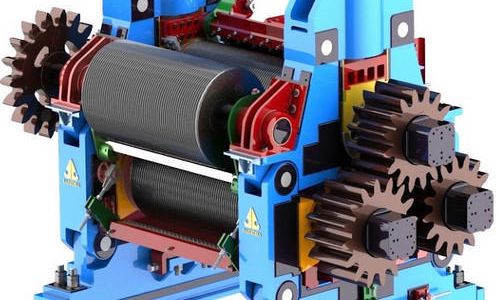

Milling tandem can be 2 roller, 3 roller, 4 roller, 5 roller, 6 roller mills with planetary gear drive system, Suitably for dounely chute with heavy duty robust construction. Maintaining zero extraction losses and achieving higher crushing rates. Low baggase final moisture and low maintenance & spares cost.

We give systems as per the site conditions and loading abilities and capacity. Material handling system involves Belt Conveyors, Return Bagasse Carriers ( R.B.C. ), Bagasse Screw Feeders, Bagasse Drum Feeders, Bagasse Silos, Bagasse De-bailers, Bagasse Briquette Crushers.

We design juice heaters as per the capacity and customer requirements. Various types are Vertical, Vapour line, Condensate and Dynamic Tubular Juice Heaters, Duplex and Direct contact juice heaters. All equipment are tested leak proof passes for maximum efficiency with multiple passage steam distribution and circulation with interchangeability and atomized operation.

Heating surfaces ranging from 100-6000 m2. Robert, Rising Film (Double Pass), Falling Film and Radial Flow Evaporators. Fully automated, non-choking design and stain less steel distributor. Radial flow evaporation is an improved design to achieve higher evaporation rate due to high heat transfer coefficient compared to normal Robert evaporators.

Syrup clarification system, Filtrate clarification system and Single tray short retention clarifier. Required automation is provided to maximize the efficiency. Better settling rates because of reduced effects of turbulence and entrapped air. Easy controls with flexibility of operation, low space requirement and low maintenance cost.

Continuous vacuum pan (dual & split), Vertical type vacuum pan and Multi down take rapid boiling batch pans. Ensure uniform throughput and product quality, operator friendly and fully automated.

Centrifugal machines are equipment which provide a high-speed rotation of the processing medium thus creating a centrifugal force which enables segregation of the varying forms/size of the processing material. Centrifuges are batch type and continuous type. Advantages are Better sugar quality, Higher capacity, lower molasses purity, reliability and safety.

carbon steel construction. The shell & end plate shall be duly stiffened. Fabricated stuffing box with gland packing. Sturdy arms shall be provided on centre shaft to support ribbon stirrer. Manhole, Ladder, Cut over, drain, inlet and vacuum nozzles shall be provided. Driven by shaft mounted planetary gear and flanged mounted motor.

Rotary sugar dryer is designed with a rotating cylindrical shell with internal lifters and also fitted with two cast steel tyres and sprocket. Rotary sugar dryer works using hot water flow which comes through the dryer. Fluid bed dryer are found throughout all industries, from heavy mining to food, fine chemicals and Pharmaceuticals and sugar industry. It is stationary equipment, provided with FD and ID pans, with various capacities.

Authorized safer and smarter filling and packaging machines with greater speed and efficiency. Innovative & Hygienic construction that facilitates easy changeovers and cleanings.

This process involves Molasses Storage and Handling Section, Continuous Fermentation Section, Multi Pressure Vacuum Distillation, Bio methanated Spent Wash Evaporation, Bio Gas Section and Condensate Polishing Unit.