AMPL offers a wide range of IBR & ASME boilers with single and bi-drum variants. Reputed as leading solution provider for energy systems and industrial boilers for low maintenance, high efficiency & reliability with fuel flexibility. Our is custom built designed to meet latest norms with fine combustion control. Range of products include Coal fired, Oil & Gas fired, AFBC, CFBC, PC, Travelling Grate, Pinhole grate, Pusher grate, WHRB, Electrical, Biomass, Vertical, Cochran, Cornish, Lancashire, Process, Packaged, LP, HP, MP boilers.

Feed water treatment system is necessary to ensure an efficient process and quality steam generation. To avoid plant downtime, expensive maintenance fees, and boiler failure as a result of scaling, corrosion, and fouling of the boiler and downstream equipment. Feed water system depends on the quality of water being drawn from in relation to the quality of water makeup needed and the system includes some types of Filtrations, Ion exchange/softening, Membrane processes such as reverse osmosis and nanofiltration, Deaeration/degasification, Coagulation/chemical precipitation.

Designed as per ASTM, IBR regulations and standards. Monitoring and Analyzing is quite common in industrial boilers as we have to monitor minute parameters, oil in water, oxygen & hydrogen levels, steam temperatures, flue gas analyzing etc all these assist to regulate and control the steam generation. Steam, water and Flue Gas Analysis systems, Water quality analysers, waste water analyzers, pressure reducers, portable analyzers, Flow meters, Temperature control valves, instrument valves and manifolds, back pressure regulators.

The fuel processing is used to acquire fuel of right size suitable as needs of boilers. We are capable of conceptualizing, designing, engineering, assembling and installing of custom fuel handling systems according to client needs for all types of fuels like Bagasse, Coal, Biomass & Lignite etc. The entire system is conceptualized based on parameters such as fuel to be handled, capacity required, availability of space, processing required, economic considerations, etc.

This system is used to collect and dispose off discharged ash and then used in various industries like construction, cement plants, and other allied industries. Ash is conveyed mechanically (submerged or dry flight conveyors, screw conveyor, belt conveyors), pneumatically (positive or negative), and hydraulically (sluice system). Fly ash is collected from flue gases by economizer, air-preheater, and ESP. Bottom ash is treated by clinker grinders and transported as ash slurry to disposal area.

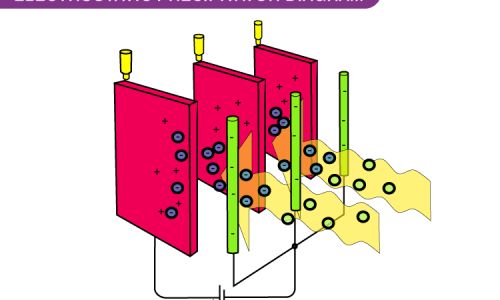

Particles of CO, SO2 are pulled out of the smoke by using static electricity in the Electrostatic Precipitators and SO2 Scrubbers, leaving clean, hot air to escape the smokestacks. Electrostatic precipitators, Bag Filters and SO2 Scrubbers are extremely effective, and are capable of removing more than 99% of particulate matter with almost 60-80% of total ash collection. However, this high level of effectiveness comes at a high cost of power plant’s electrical energy output. Effectiveness is also determined by the temperature and moisture content of the flue gas.

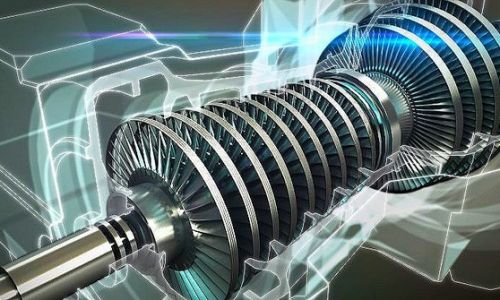

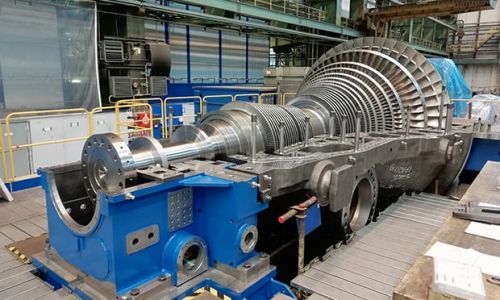

Engineered to optimize heat & power solutions with various pressures, flows and cycles. Our product range of turbines include Straight, Extraction and Bleed Back Pressure and Condensing Turbines and Injection Condensing Turbines of up to steam inlet temperature and pressures of 545⁰C and 120 Bar with various design standards include Turbine and its control systems, Horizontal & Axial Casing, gearbox, Alternator, Lubrication system, Control oil system, Condensing system and Electrical/Metering/Control/Protection system.

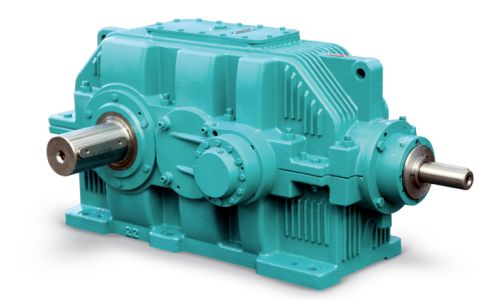

AMPL has a long engineering and service tradition of gearboxes of various speeds and torques, gears, gear drives for material handling equipments, boiler feed pump, coal mill & pulverizer, turbine and accessories, fibrizor drive, cane shredder & cutter drive, ash & fuel handling equipments, compressor/accessory drive, blowers, circulating oil/screw oil pumps, turbine generators, mills, turbo compressor & blower drives, id/fd fan drives, briquetting press/share press, coiler/un-coiler, leveler & edger, mixer & extruder, auxiliary & crane drives and general industrial purposes.

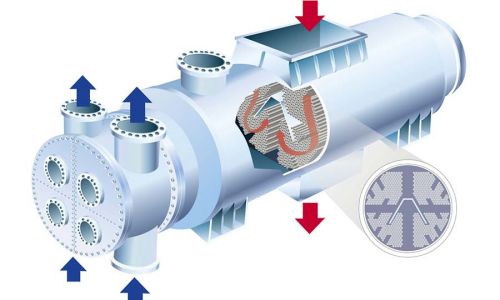

The performance of condenser is a significant factor in the overall operational efficiency of a power plant. Improper and outdated tube bundle layouts limit condenser and turbine back pressure and thus the electrical output of the plant. Shell and Tubes are engineered and designed to improve quality by eliminating zero contamination. It has accessories include central control panel, vacuum & extraction pumps, high- & low-level switches, atmospheric relief valve over-pressure protection for the steam and steam jet ejector.

Our generators install quickly, integrates easily, operates reliably and delivers more power. AMPL fully integrates engineering, to life cycle services to offer a complete range of services delivering innovatively and keep your generators operational for the life of the equipment and to add much more value to you. Choose from our product range of large generators for power production and industrial generators.

We offer you the best tower design and have developed an innovative range of products that cater to the needs of high-profile industrial demands. Our complete range of solutions to process water-cooling is by way of designing the cooling towers as per the standards. Our products are Fibre Reinforced Polymer (FRP) cooling towers, Pultruded cooling towers, Timber cooling towers and Reinforced cement concrete (RCC) cooling towers.

Water treatment systems offer power plant owners and operators a reliable and well-proven water treatment solution. However, designing and caring for water treatment system requires a thorough understanding of a plant’s water supply and the technology’s capabilities. Our range of products include RO system, Membrane system, Ion Exchange, Reverse Osmosis, Nano Filtration, Water Filters, Custom filtration, Water Disinfection.