Since its inception AMPL is providing wide range of customized solutions across the globe for multiple industrial segments

Since its inception AMPL is providing wide range of customized solutions across the globe for multiple industrial segments

AMPL delighted their customers in Power, Palm, Sugar segments along with Cement and Petro Chemical Refinery Segments too and maintain cordial relationship with clients. We utilize our wide range of Engineers & Experts to meet any kind of job requirements related to Industrial Equipment’s and deliver professional services at shortest possible time throughout the complete lifecycle of plants.

Engineering, Procurement and Construction

AMPL offers wide range of engineering, Procurement and Construction projects upto 100 MW capacity cogeneration power plants, 10TPD sugar mill, 10TCD Palm mill, General equipment and Piping Works. Our Design, Engineering, Technical Staff and Management strives to achieve every possible outcome. We offer works in fields with SOP’s for the full scope of mechanical, electrical & instrumentation tasks in all business segments of power, cement, palm, sugar and petrochemical industries.

Erection, Testing & Commissioning

Budget friendly customized solutions with timely delivery all over the world into multiple business segments like Power, Palm, Sugar, Process industries and Cement & Petro refinery. With more than 25 years of experience in ETC on different business segments we are unique when compared to other competitors in this line of services. We work in the concept of helping together succeed in businesses. We resolve problems and move forward confidently with the help of our Experienced Managers, Engineers, Technical crew.

Budget friendly customized solutions with timely delivery all over the world into multiple business segments like Power, Palm, Sugar, Process industries and Cement & Petro refinery. With more than 25 years of experience in ETC on different business segments we are unique when compared to other competitors in this line of services. We work in the concept of helping together succeed in businesses. We resolve problems and move forward confidently with the help of our Experienced Managers, Engineers, Technical crew.

Fabrication Works

Structural engineering, Metal & Plastic assemblies, Machining & Piping works are common in this field and is a integral part of these industries, we do fully operational fabrication services with modern methods at our workshop and we have professional work force for site locations for wide range of materials. We consistently update and maintain our workforce with proper training for futuristic works with modernized technologies.

Piping Works

Piping is not just an easy task every service provider can do, with our vast knowledge on thermal calculations, insulation, material standards and design standards on various piping technologies makes AMPL unique and competitor free in this segment. Our working experience resulting in unmatched and outstanding performances in Piping works all around the globe for vast variety of industries like power, oil & gas, Petro refineries and more. We have expertise in civil and structural works too.

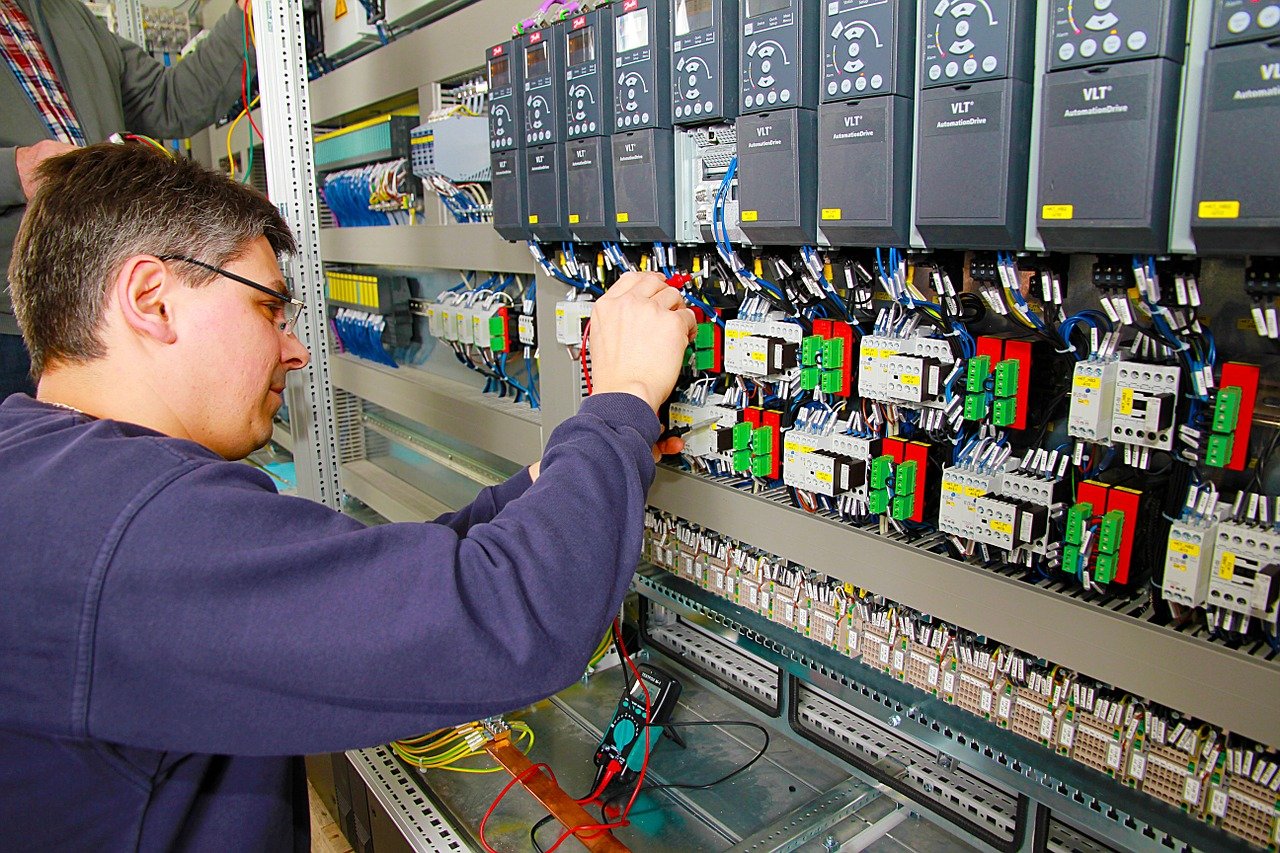

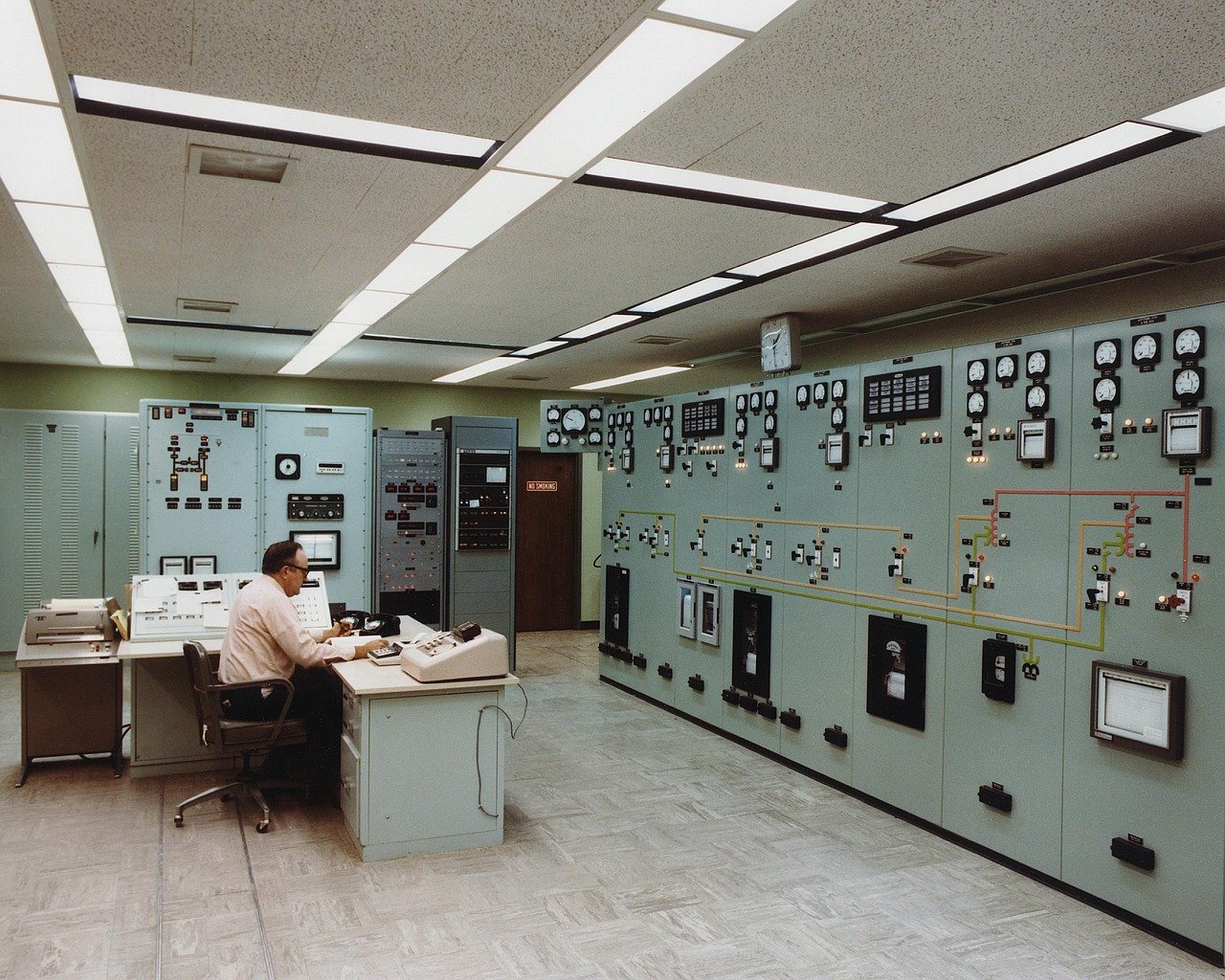

Electrical and Instrumentation

Electrical, Control & Instrumentation is the nervous system of any power plant that links all systems and components. It measures the critical plant parameters, automates the processes & procedures, protects the plant assets by generating alarm & trips and most significantly the man-machine interfaces (SCADA & DCS). AMPL offers a large variety of services includes the whole set of field instruments, cabling, calibration, commissioning, panels and operative stages up to control and regulate system retrofit. Our expertise in varied industries explains our in-depth knowledge essential for providing clients with the very highest standards of service.

Boiler, Turbine, Generator Services

AMPL offers a total repair assistance for Boiler, Turbine and Generator. From basic cleaning, maintenance to repair, retrofit and refurbishment, we offer our complete engineering support for top notch performances of minute parts to major equipment with minimal downtime and safe operation. From leakage check to refurbishment of boiler, from Re-blading of turbine rotor to alignment, from electrical checks to repair of coils, insulation, rotor and stator of Generator

Operation and Maintenance

Optimal Performance for over the lifetime of the plant comes only with proper operation and maintenance with core competency. Our world class performance makes equipment completely reliable and safety in operation through out the lifecycle of plant. We maintain works in fields with SOP’s for the full scope of mechanical, electrical & instrumentation tasks in all business segments of power, cement, palm, sugar and petrochemical industries. With our rapid team we can overcome unscheduled troubleshoots, breakdowns and repair faults to minimize running downtime.

Electrical Diagnostic Testing

Electrical components undergo the process of deterioration due to the continuous operating voltage stresses, ambient temperature & moisture, transients, surges, spikes, etc. Electrical testing is an effective tool for evaluating the condition of the insulation & conductor of electrical machinery and appraises its fitness for the further usage. Our capabilities include the complete range of testing from insulation resistance test to tan delta and El CID test. We offer testing of motors, transformers, relays & circuit breakers, generators. AMPL offers a large variety of services includes the whole set of field instruments, cabling, calibration, commissioning, panels and operative stages up to control and regulate system retrofit.

Controls and Instruments Calibration

Like periodic maintenance checks for BTG elements, periodic calibration of controls & Instruments is very important task to cope up with the safety and quality operations. Calibration is necessary transmitters, analog & digital parts, earthing points, excitation panels and terminals to ensures the instrument measurements to be accurate and within the range of limit value required to maintain the safe plant operation. .

Rotating Equipment

Rotating machineries like turbine, compressors etc. have to deal with vibration and balancing. We offer basic and portable condition monitoring, Machine protection systems and sensors, dynamic balancing and vibrational analysis for rotating equipment’s with machine protection systems having wide variety of options like on site diagnosing, balancing and machining.

Plant Works

AMPL offers a wide range of maintenance works all across the plant like material handling of heavy equipment, drying & dehumidification, power transmission systems, reverse engineering, condenser & Cooling towers, control panels and retrofits, all auxiliary equipments and associated piping with supports, lubing of parts, micro & macro inspection, hydraulics & pneumatics, compressors & gearboxes etc.

NDT & RLA Facility

Rotating equipment’s, pressure parts, machined parts, industrial structures & pipelines experience sudden & extreme load and need to with stand creep and fatigue during the lifetime operation. Non-destructive testing (NDT), is a highly valuable technique that is used to evaluate the internal condition of materials and to detect instabilities, to recognize failed components, or highlight an inadequate system. Residual Life Assessment determines the time period during which it shall retain the fitness-for-service characteristics, in order to ascertain the remaining life and

to monitor the extent of in-service deteriorations. Frequent or periodic maintenance checks with most of these modern inspection techniques of major and key components help to find the exact condition, internal flaws and cracks, service lifetime and early breakdown of components thereby prevents major breakdown.

Renovation & Refurbishment

Modern economic perspective of plant operation and strict environmental requirements that forces the plant managers to seek balance between investment against performance and downtime. Monitoring of the critical plant equipment is important to track the aging process and implement the corrective actions. Most of the plant owners never think of plant performing efficiency, most of plant runs at low performance with huge losses of energy in any way. By retrofitting procedure performance enhancement is possible by reducing the losses and to increase the efficiency of already running equipment’s. Renovation and Refurbishment of existing power generation facilities, is a cost-effective alternative to increasing the operational life of Power Plants. Through this method generation equipment undergoes technological upgrades to boost capacity and reduce emissions. Our projects are tailored to revamp degraded efficiencies and optimize existing generation capacity, thereby ensuring long-term profitability hile keeping capital costs low.

Relocation & Shutdowns

Decommissioning & closing a plant is a highly complicated task as it involves handling of live electrical system, fuel gas purging, depressurizing of vessels, draining the tanks, venting the pipelines, etc. All the plant equipment must be decommissioned and liquidated or redistributed. Whether it is a complete turnkey plant relocation project or the relocation of a single item of plant, AMPL have specific team to handle the task safely and timely and follows an extensive code of environmental, health and safety policies to meet regulatory requirements for all the aspects of relocation from decommissioning to site restoration. We assist the plant owner in identifying the potential client for selling plant machinery & extends the support till reengineering & installation at new site location.

Used Plant

We assess the residual life of the critical equipment and execute renovation & modernization projects to increase the life of plant either by replacing with the used equipment or with the new one. AMPL has experience with clients who sells the used plant equipment and make reinvestment on the same plant or new plant. We offer the complete solution from decommissioning, to dismantling, packing, transportation and reinstallation at new project site. We also help our clients in identifying the potential buyers for their used equipment.

Field Support & Engineering Solutions

AMPL offers full range of support and field solutions for all industrial maintenance, troubleshoots and performance checks and renovative refurbishments of equipment’s and processes. We offer our full support solutions in wide range of spectrum of industries includes the power generation, oil & gas, cement, palm, sugar, steel, and petrochemical refineries. Our field service makes AMPL unique than other service providers based on the reputation for assisting outage support during emergency breakdown, and when needed for performance improvement and periodic checkups. Trust, Response, top-notch management, highly skilled workforce, spares supply capability and high standard service works has recognized us to be a most trusted and reliable names in industrial service segment.

Maintenance Contracts

Our field services team covers the complete spectrum of service works in plant.

Highly skilled & experienced team of engineers & technical crew can plan & execute in every shortest possible time. Proper strategic planning is essential to execute the outage with minimum downtime and keep the machine running safely and reliably. Long term service agreements, including technical support and parts agreements, help manage risk during normal plant operations and emergency situations. We offer service for full range of plant and deliver rapid service and provide sourcing of critical parts, control upgrades, and field services.

Get in Touch

If you’ve got questions or ideas you would like to share, send a message. For anything more specific, please use one of the address listed below.

Abhignas Machineries

D No -19-83/3, Mahendra Nagar, Gollapudi, Vijayawada, Krishna District, A.P.

Support

+91 91212 12700

Our Email

sales@abhignas.com

info@abhignas.com

Let's Talk About Your Project

After we get some information from you, we’ll set up a time to discuss your project in further detail.