Sterilizer equipment in palm oil mills operated in single, double or triple peak cycles as batch process to cook palm bunches using high temperature steam. Sterilizers are of various types like Tilting sterilizer hydraulic system, tilting sterilizer Hydraulic Cylinder, Vertical Sterilizer – External Auger or with additional exhaust and Revolving Sterilizer . Our innovative, high quality palm oil sterilizer machine are easy to maintain and can finish the most energy efficient palm oil sterilization with high performance and low failure rate. easy to maintain, etc.

Tipping process is controllable and regulated (programmable during setup for the best tipping process) for each tipping cycle and throughput is enhanced. The tipper speed is programmable for a fast, slow and even halt during tipping. Solenoid operated with dual speed capability, which is then controlled by electrical joystick via a floor stand control panel or PLC panel. Using of PLC allow automatic and manual operation.

Hydraulic drive for Conveyor systems has been chosen lately over electrogear motor due to hydraulic high starting torque compared to gear-motor that is helping to prolong the life span of conveyor chain used.

A variety of different cage sizes used in a typical palm oil mill. For cage size from 3.5ton to 17.5ton are typically single cage or twin cage or triple cage per transfer carriage movement.

A few different types are: Tilting type transfer carriage, Undertow type transfer carriage, Indexer type transfer carriage, Empty type transfer carriage, Transfer Carriage c/w Rotary Lock Hydraulic System is designed to provide a faster yet smoother cage transfer operation from one lane to another.

Undertow conveyer system Hydraulic power unit (HPU) to drive the high torque low speed hydraulic motor that is directly attached to a sprocket of undertow conveyor chain mounted on a frame with tipping dogs to push the cage. The movement could be forward and reverse via the directional control valve. Electric motor sized up for maximum system operating pressure at 250 bar. Built-in over-load & over-torque protection adjustable safety relief valve incorporated within. HPU is normally located near the actuator with smooth and reliable controls.

For Horizontal Sterilizer or Non-Horizontal Sterilizer the SFB are typically sent to the Threshing Station via Conveyors to Thresher for the activity of emptying the FFB into the threshing machine which will separate the fruitlets from empty fruit bunches.

Digesting involves the crushing of fruits before oil extraction and works on a rotary impact principle includes a heated cylindrical container equipped with a central rotating rod carrying some stirring or beating arms.

Screw press is the most recommended palm oil pressing machine as it yields most oil, nuts can be removed before digesting to yield grade A oil or the mesocarp can be pressed together with nut.

Milling machinery uses 2 screw feeders, spacing between screws is hydraulically controlled and suitable for various palm fruit sizes and types. After pressing, the palm kernel and fiber mixtures are sent to palm kernel recovery section and the crude palm oil is sent to the palm oil clarification section.

Separators are compact production machines which make mechanical separations according to particle size through multi-plane inertial vibration techniques. They are designed and the most difficulty classifying, separating and dewatering. Separators are used to make accurate separations ranging from 2″ clear openings to 25 microns, models of various diameters built of stainless steel.

Process includes the sludge dewatering, thickening, heating, cooling, heat recovery, digestion and pasteurization. The control systems for optimizing dewatering & reducing manpower requirements. On-site thickening and dewatering of sludge is a fundamental part of all current wastewater treatment processes to reduce sludge volume, waste disposal cost. We offer robust, well-proven technologies that effectively separate off the liquid phases and achieve a high level of dry solids content.

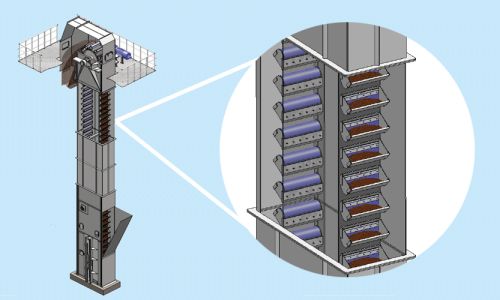

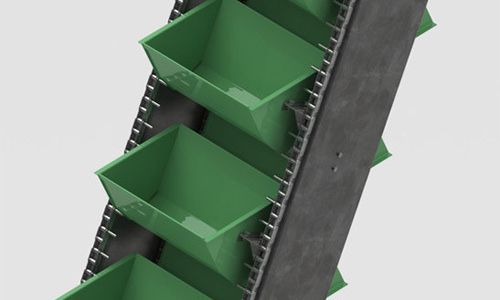

Designed for palm kernel shell conveyance a large amount of material compactly at high speeds. Shock Relay overload protectors, Cam Clutch backstops, Speed Switch deceleration detectors, Touch Switch belt misalignment detectors, bearing temperature sensors, etc are the essential items. Driver can operate at any speeds and very smooth in operation with absolutely low noise.

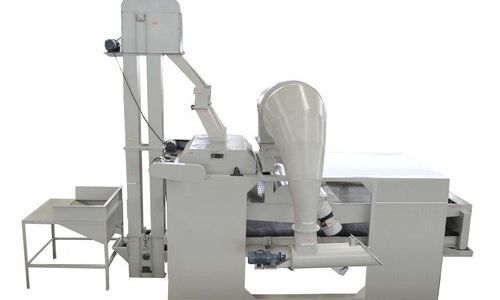

Seed treater machine is used to break the palm nuts into small pieces. With this design the process of cracking becomes simplified and mechanized. Palm nuts directly fed into nut cracker through hopper, the high-speed rotating disc located at the center of the machine made of hardened steel throws away nuts towards the wall. This sudden impact leads to the breaking of the palm nuts due to centrifugal action.

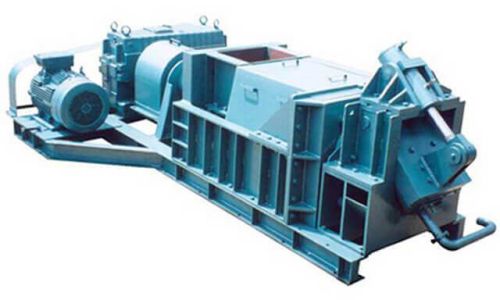

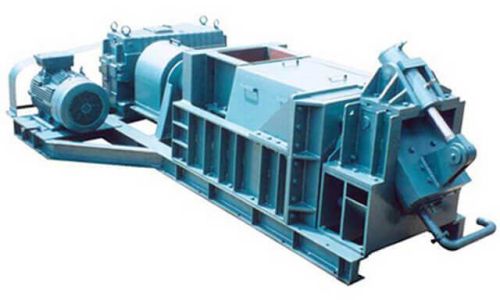

EFB Shredder also known as Break Cutter cum Oil Extractor or Size Reduction Break Cutter is a compact and heavy-duty processing machine namely breaking, squeezing, and cutting. EFB is fiberized and shredded into short fibre in discrete pieces. Along the shredding process, a mixture of oil & water is squeezed out and directed to the mill’s oil recovery system.

In the primary stage, the EFB Single Barrel Press is used to squeeze out the remaining oil and reduce the moisture content, and for boiler fuel application, the shredder will further reduce the moisture content of the pressed fibres and shred it into discrete pieces of 2-4 or 1-2 inches respectively. Shorter fibres improve burning efficiency in the boilers. This biomass material can be used for energy generation, composting, mulching, pelletizing, etc.

The cake from the press become dense a well compacted mass that needs to be broken before separation. It functions to loosen the press cake to separate the nuts from the fibre and delivers to the air separation column. “L” shaped paddles on the rotating shaft opens up the fibre and loosen it from the nuts and keeps the fibre in a state of agitation. Certain amount of moisture will be lost by evaporation as the loosened fibre passing along the cake breaker conveyor towards the nut separator.

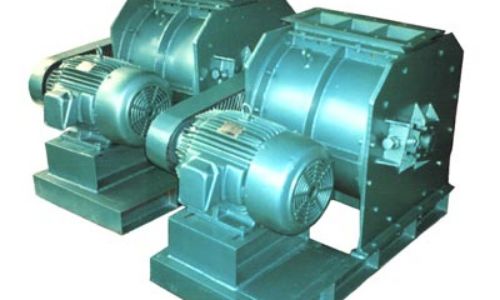

This equipment is primarily for extraction of palm kernel oil comprising primarily the pressing stations, coupling, gearbox, pulley and belt, and motor. The main shaft directly driven by a coupling affixed to the gearbox on minimizing the maintenance costs and time.

Wire rope winch system is designed specially to pull sterilizer rail track. Design suits the robustness of usage and safety in pulling. Designed of Hi-performance, High Torque and Low Speed radial piston motor with the option of free-wheeling. Built-in over-load & over-torque protection with adjustable pressure relief valve for preventing wire rope to snap and full drum reversal at maximum line speed capability. 12-ton line pull capacity for 180tonf Hydraulic system used in this application required to drive at efficiencies.

Ripple mills is for cracking of palm nuts, up to 98% of cracking is achievable. It has high wear resistant and interchangeable rods that makes it have longer life span. It is easy to operate and the maintenance required is minimum.

Weighbridges work dependably and accurately, even in tough industrial environments. Each is built to last with a rugged design, robust weight sensors and high-quality material suits for application and is fully factory assembled and performance tested. These rugged scales can be either surface or pit mounted, depending on the location and use of the scale with a complete range of indicators, software and data management systems.